Repeaters from the inside

Andrew Babanin

Unfortunately, repeaters are fairly rare and expensive so opportunity to own and service any of them is welcomed. Here I represent three repeaters: two quarter and one minute.

The first one is an open faced travel watch in a square case with opening back to put it on the table.

Fig.01. Travel pocket quarter repeater

It’s a cheapie Cyma. I do not like Cymas at all but this one seemed to me very interesting. The watch is not in very good condition. Gunmetal has some rust spots and somewhere it is worn away, so it needs to be polished and blued. The dial is black and has Roman numerals with single sunk small seconds. To pity it has a quite big crack on 4, but no chips. Nice Breguet style hands are just a replacement – It has no hands at all when I’ve bought it. The case marked with a serial number 20216.

Fig.02. A movement covered with the glass back

A few words about the movement – it's quite common CYMA 13 jewels quarter repeater. The gilded brass movement is a Swiss bar type with individual cocks for the escape and fourth wheels. The balance has screws on the rim but it’s uncut, however, the hairspring is alloy, which needs an uncut rim for temperature compensation and has overcoil like in better calibers.

The problem with servicing repeaters is – it is very uncommon and has a lot of very special levers, springs. So even plain cleaning can give you a real headache. You need to keep each part with its associated screw separately during disassembling and cleaning. If you’ve got a small experience in repeater TLC - it won’t take more time than a servicing chronograph. Do not forget to photograph or to make drafts during servicing – it will save your time and nerves.

Fig.03. Under the dial: T- trigger push-piece, MR- matching rack, SW - star wheel, Q- quarter snail, CR - circular rack, PH & PQ - hour and quarter pawls, QS - quarter stop

The push piece here is made as a trigger lever. So you should move aside a trigger and it will come back during chiming. This movement has no governor – just a lever like in alarm clocks. So it buzzes. It has very loud chime, besides it's not very fast. Both cams in this movement from the one side – one over the other. So strings are also come out the only side.

How to wind repeater

The repeat mainspring is wound by pulling the trigger, which pushes the matching rack. By its teeth it interacts with a half pinion, mounted on the repeater spring arbor.

Interacting the hours and quarters

Fig.04. Pushing the trigger. Notice that sensitive fingers are touching their snails

There are two snails: an hour snail (underneath a star wheel) and a quarter snail on the minute pinion. Hour snail has 12 segments, quarter – 4 ones. The star wheel is positioned by a jumper, which causes it to jump forward the whole hours.

Theoretically it's necessary that in the moment when star wheel jumps forward – quarters also should change 3 quarters onto zero. For this purpose there was constructed a surprise piece, mounted underneath the quarter snail on the cannon pinion.

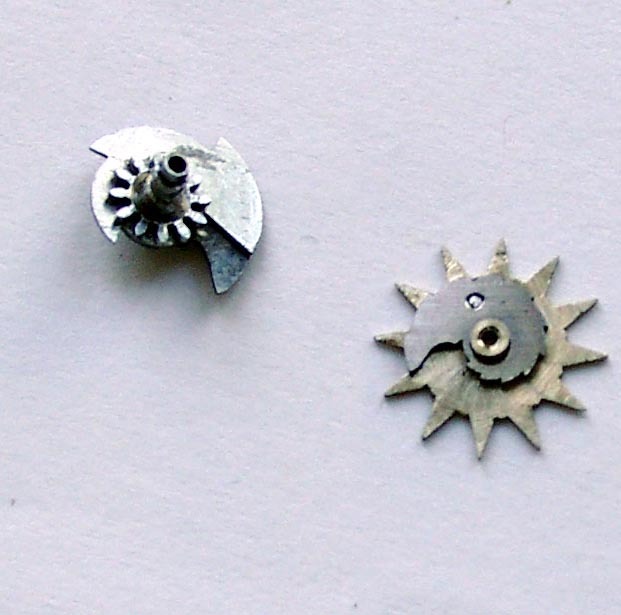

Fig.05. Cannon pinion with quarter snail and surprise piece (shown underneath), star wheel with 12 segment snail

The surprise piece is thrown out by the movement of the star wheel at the moment it jumps forward. It means that no quarters are sounded the moment the new hour is indicated by the hour snail. Here I will stop a long tale about CYMA.

Here’s a new one quarter repeater. It has a more common construction and it's easier to describe you the principles.

Fig.06. Traditional repeater with governor

This repeater is in a silver hunter case. Unfortunately, the producer was very modest and forgot to print his brand name on the dial. Bless him. I didn’t photograph the dial because of it’s quite poor condition. But under it… Oh it’s a real miracle.

What else about the movement – a plain Swiss made caliber with a governor. Balance has overcoil – nice tradition for repeaters. Ratchet wheel is fastened in place by a boss with two holes.

But let us continue about the repeater works.

If you have read a few words before, you can easily find a star wheel with a snail (here it is vice versa), a quarter snail. What else? A push piece is made as a button. It interacts with a lever, which in its turn, interacts with a matching rack. It also winds a spring thru the half pinion. I photographed separately a cannon pinion with a quarter snail and surprise piece. Also here there’s a large pic of star wheel (see fig 5).

Inspecting dings-dongs

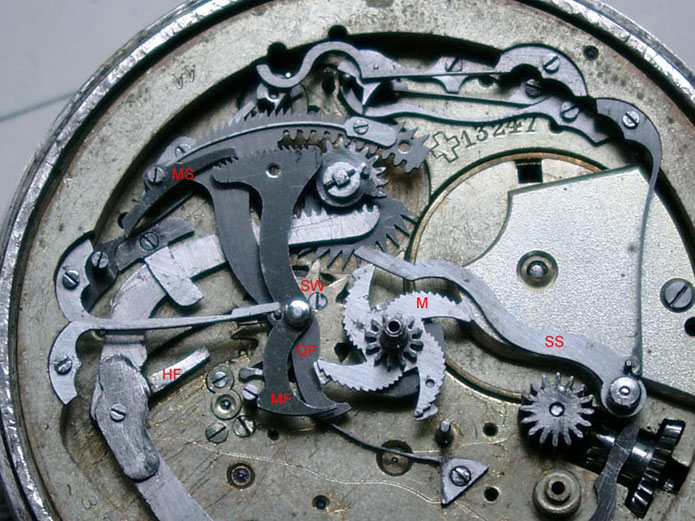

Fig.07. A closer look: MR - matching rack, SW - star wheel, Q - quarter snail, CR - circular rack, QS - quarter stop, HF - hour sensitive finger, QF - quarter sensitive finger, PH & PQ - hour and quarter pawls, P - pin, "1" - hour teeth, "2" & "3" - quarter low & high strike teeth, "4" - quarter stop slots

You can notice a circular rack, mounted on the squared repeater mainspring arbor. Its teeth interact with two pawls: hour and quarter. These pawls are attached to the hammers that strike the wire gongs. When you push on the button – it rotates CCW, when release – CW. Here teeth engage with the hour pawl. We hear low pitched gong. The quarter pawl is placed a bit off, so it's not engaged.

Except for 12 hour teeth the circular rack has two sets with 3 teeth (quarters). One set – for low pitched gong, the other one – for high pitched gong. The teeth are positioned so that they operate their pawls alternately. First Ding, then Dong.

You can notice a pin on the circular rack plate. It interacts with a quarter stop lever, mounted on the quarter sensing finger. It prevents further rotation of the circular rack. There are 4 slots in a quarter stop – the closer one (the foot)– no strike – close to the tip – 3 quarters. So you can imagine: if it engages with a pin nearby its foot – it allows the circular rack to rotate a small angle, if it’s closer to the tip - than a bigger angle – more strikes.

Fig.08. Ready to chime 3 hours and 3 quarters (released)

Fig.09. Sensitive fingers touched snails (wound)

I photographed two stages of the repeat works: wound and released. So you can see how sensing fingers touch their sections on the snails. Here I will stop my tale about noname repeater.

Le Phare

Let us allow to come a novice on the stage: The well known Le Phare minute repeater with a chrono function. I’ve bought it in a handmade silver case. Oh it is very heavy :). As always there are problems with hands. I placed temporarily another minute hand. Now it has normal hands. Only small seconds is still missed :(.

Fig.10. Standard Le Phare movement in handmade silver case

The dial has small chips but no cracks. As to the movement – it works well. There was the only problem – the column wheel lever is missed. I had to make another one. I do not have the original so now it looks too modern. Hope to find a normal one. Anyway – everything works perfectly.

The other chapter is a governor

Fig.11. Chrono module and jewelled governor

It’s not a secret – that Le Phare has invented a centrifugal governor system. It slows the rate of striking so that hours, quarters and minutes can be counted easily. But I have to notice that an alarm lever slowing system is slower than the governor (pardon for repeating). Even in spite of the buzzing sound it is more comfortable to listen. But … let's return to our Le Phare. The slowing movement consists of a governor, its train and a cage. You can notice a big jewel in the cage. The two small weights in the governor are mounted on the hinged arms which fly out controlling springs as the regulator spins, until the weights rub on the wall of the cage.

The aim of the governor is not only to slow the speed of spinning but also to keep constant rate of rotating.

Let’s take a look under the dial. Ummm.

Fig.12. Under the dial

Notice that four minute snails made as a cross, are mounted on the cannon pinion. There are FOUR!! Surprise pieces underneath these snails. Now you know a purpose of this device. Each snail has 14 sections – 14 minutes.

Under these snails – there is a well known quarter snail (also with a surprise piece). In spite of the fact that the minute repeater differs from the quarter only with addition of one rack and these snails – it takes us to a much higher level.

Fig.13. Under the dial (Close up): SW - star wheel, M - minute snails, HF, QF and MF - hour, quarter and minute sensitive fingers, SS - surprise piece spring (for minutes), MS - minutes stop

Fig.14. Notice a minute surprise piece

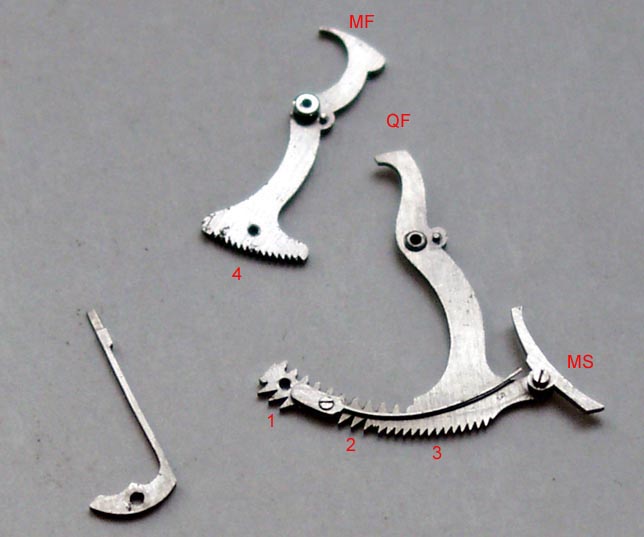

Pay attention to the sensing fingers – there’re 3 ones: one is made as a matching rack, others – as rack levers. Also pay attention to minute stop lever. It has 15 slots. It works like a quarter stop lever and also allows the circular rack to turn on a certain angle (to strike certain qty of minutes).

Fig.15. Some parts dismounted. Here:

MR - matching rack, HP - half pinion, HT - hour teeth, PH&PM - hour and minute pawls, B - mainspring barrel (do not mix with repeat mainspring!)

Notice three sets of teeth: one fixed to the square arbor of the repeat mainspring, two others are placed on the quarter rack lever: two sets with 3 teeth – for quarters and one set with 14 teeth for minutes.

Fig.16. A close-up of racks:

minute rack with: MF - minute sensitive finger, "4" - 15 slots for stop minutes, quarter rack with: 3 sets of teeth: "1" & "2" for quarters (low and high strikes) and "3" - for minutes, MS - is a minute stop

In conclusion

When you work on the repeater do not forget to wind up a repeat mainspring on one - two of turns. It’s enough to be sure that even the longest strike (12:59) will accomplish. One turn for a normal gear. Two turns – to compensate some wear – to make strikes constant. Before disassembling a repeat barrel – dismount all parts of the repeat works – it will save the repeat wheel train and the mainspring.

I will be very grateful if you send me by mail some additions or notes.

Back to list

English

English –†—Г—Б—Б–Ї–Є–є

–†—Г—Б—Б–Ї–Є–є